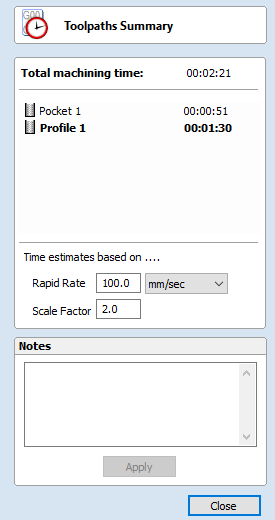

Estimating Machining Times

This option estimates the machining times for all calculated toolpaths based on the feed rates specified for each tool. The estimates for individual toolpaths plus the overall machining time of all visible toolpaths are calculated using the user defined Rapid Rate moves and Scale Factor.

Times

The estimated machining times are displayed in Hours: Minutes: Seconds

Rapid Rate

The maximum feed rate at which the machine runs for rapid moves, typically specified using a G0 or G00 move

Scale Factor

The nature of different styles of toolpaths means that they may be simple 2D cuts or require simultaneous 3-axis moves, the more complex the toolpath then the more chance the CNC machine may not actually achieve the programmed feed rates. This can be compensated for by multiplying the times by the Scale Factor.

The inaccuracies generally come from the acceleration / deceleration of the machine. If the program tells a machine to move at 200 inches / min along a 200 inch straight line the machine will probably take pretty close to a minute.

If instead of a straight line we ask the machine to cut say a gear wheel with a total circumference of 200 inches, the machine is likely to take considerably longer. This is because the machine will have to slow down to go around the tight curves of gear tooth profiles and will probably never reach its programmed speed before having to slow down again for the next change in direction.

The scale factor in the program lets you approximate this slowdown for your machine, but it will vary depending on the type of work you are doing. Many people will use one scale factor for simple 2d work and another for 3d or VCarving. The best way to calculate it is just to take a note of estimated and actual machining times of a period of time.

If a job actually takes 6 minutes to cut and the estimate was 3 minutes, the scale factor would be set to 2 (actual time / estimated time = 6/3).

For machines where the controller provides an estimated machining time, these should be more accurate as the controller can determine where the machine is accelerating / decelerating and take account of this.